Pre-construction utility potholing is a vital process using vacuum excavation to map underground utilities before building. This non-destructive method identifies pipes, cables, and other critical infrastructure, minimizing environmental impact and reducing risks of damage, delays, and safety hazards during construction. By employing skilled potholing services, contractors gain precise subsurface utility data, enabling efficient project planning and execution while ensuring safe utility exposure.

Enhancing site safety with precise utility exposure is paramount in modern construction. Before breaking ground, understanding and managing underground utilities is crucial to avoid costly damage and ensure worker safety. This article explores four key strategies: pre-construction utility potholing as a foundational safe exposure method; non-destructive locating techniques for accurate identification; vacuum excavation, a cutting-edge solution; and the importance of subsurface utility verification for unparalleled precision. Implement these practices for efficient, secure construction projects.

Pre-Construction Utility Potholing: The Foundation of Safe Exposure

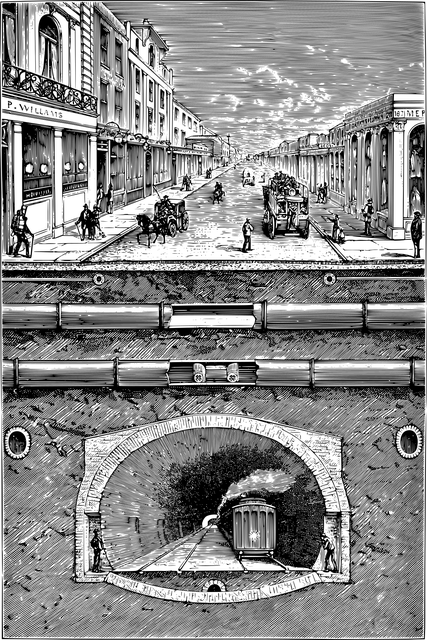

Pre-Construction Utility Potholing serves as the cornerstone for achieving safe and precise utility exposure during construction projects. This non-destructive method involves utilizing advanced vacuum excavation techniques to reveal and map out crucial underground utilities, ensuring that construction activities don’t inadvertently damage critical infrastructure. By employing skilled utility potholing services, construction teams can accurately identify and locate pipes, cables, and other subsurface utilities before breaking ground.

This proactive approach is essential for minimizing the risks associated with utility strikes, which can lead to costly delays, safety hazards, and even permanent damage to vital systems. Pre-construction utility locating helps in verifying the exact locations of subsurface utilities, enabling more efficient planning and execution of construction projects. With vacuum excavation for utilities becoming the preferred method due to its minimal impact on the environment, achieving safe utility exposure has never been more feasible.

Understanding Non-Destructive Locating Methods

Understanding Non-Destructive Locating Methods

In the realm of construction and site safety, precise utility exposure is paramount to avoid damage and ensure worker safety. One of the most effective methods for achieving this is through non-destructive locating techniques, such as pre-construction utility potholing and vacuum excavation for utilities. These services play a crucial role in identifying and verifying subsurface utilities before any construction begins, enabling safe and efficient project execution.

Pre-construction utility potholing involves creating small holes to expose buried lines, allowing for visual inspection and accurate mapping. This method, also known as potholing for construction, is essential for locating and documenting various utilities like water, gas, electricity, and telecommunications cables. Additionally, non-destructive utility potholing ensures subsurface utility verification, providing a clear understanding of the layout and condition of critical infrastructure, which is vital in avoiding costly damage during construction activities.

Vacuum Excavation: A Modern Approach to Underground Safety

Vacuum excavation is a modern approach to underground safety that offers a precise and non-destructive method for locating and verifying utilities before construction begins. This innovative technique, also known as utility potholing or pre-construction utility locating, involves using powerful vacuum equipment to carefully extract soil around buried utilities without damaging them. By employing vacuum excavation for utilities, construction projects can significantly reduce the risk of hitting critical infrastructure during excavation, ensuring safe utility exposure.

This method is particularly valuable in urban settings where the location and depth of underground utilities are not always clearly marked or documented. Potholing services allow contractors to accurately map out the precise location and condition of pipes, cables, and other subsurface utilities before digging. This proactive approach not only prevents costly accidents but also streamlines construction projects by eliminating delays caused by unexpected utility strikes. In terms of safety and efficiency, vacuum excavation for utilities is a game-changer in the pre-construction phase, providing reliable subsurface utility verification.

Ensuring Precision with Subsurface Utility Verification

Ensuring precision in utility location is paramount to safe and effective construction projects. That’s where subsurface utility verification through pre-construction utility potholing comes into play. This non-destructive method, often employing vacuum excavation for utilities, allows for accurate identification and mapping of underground lines before any disturbance.

By utilizing utility potholing services, construction teams can gain precise knowledge of the location, depth, and type of underground utilities. This minimizes the risk of damaging critical infrastructure during excavation, leading to safer working conditions and reduced project delays caused by unforeseen utility conflicts.

In enhancing site safety through precise utility exposure, pre-construction utility potholing serves as the foundational step, ensuring a thorough understanding of underground infrastructure. Combining advanced non-destructive locating methods with innovative techniques like vacuum excavation allows for safe and efficient access to utilities. Additionally, verifying subsurface utilities through rigorous processes guarantees accuracy, thereby minimizing risks associated with construction projects. By adopting these comprehensive strategies, including pre-construction utility potholing services and subsurface utility verification, construction professionals can navigate complex landscapes while upholding the highest safety standards.